MIZUNO PRO- A NEW AGE OF FORGING

The foundation of the Mizuno Pro 241/243/245 irons is a unique, long-standing connection between Mizuno's club engineers and its Grain Flow Forging plant in Hiroshima, Japan. A relationship which enables increasingly sophisticated designs to be crafted flawlessly into finished equipment. Where every fraction of a millimetre and subtle curve matters.

"Other manufacturers have widely adopted Mizuno's work to elevate the performance of elite player's irons. What now sets Mizuno apart is the ability to apply precise manufacturing techniques learned at our long-standing forging plant in Hiroshima, Japan, to increasingly complex designs.”

DAVID LLEWELLYN – Director of R&D

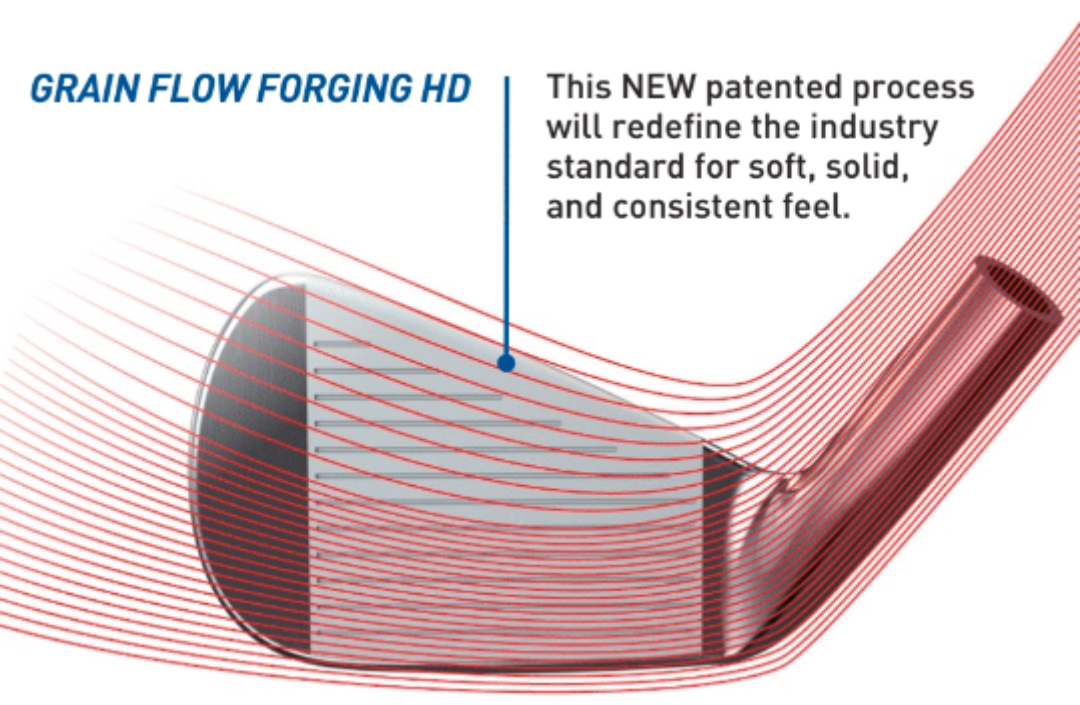

Mizuno's Unique “Grain Flow Forged” Manufacturing Method

Mizuno's unique forging method integrally molds a single round bar from the face to the neck. The long-lasting sound of the ball allows you to experience the comfortable hitting feel that’s unique to Mizuno. The grain flow lines (metallic structure flow) are not interrupted inside the head, and the Grain Flow Forged HD manufacturing method allows the flow lines to be densely packed in the ball hitting area, making the sound of the ball resonate for a long time.

Continued Evolution- World Patented Hitting Feel

Patent 6391871

The chromium molybdenum steel used in the Mizuno Pro 243 and Mizuno Pro 245 is said to be a difficult material to process. With Mizuno's forging technology, chrome molybdenum steel can be forged using our unique grain flow forged manufacturing method. As a result, we created the Mizuno Pro, which combines good hitting feel with a thinner face and distance performance.

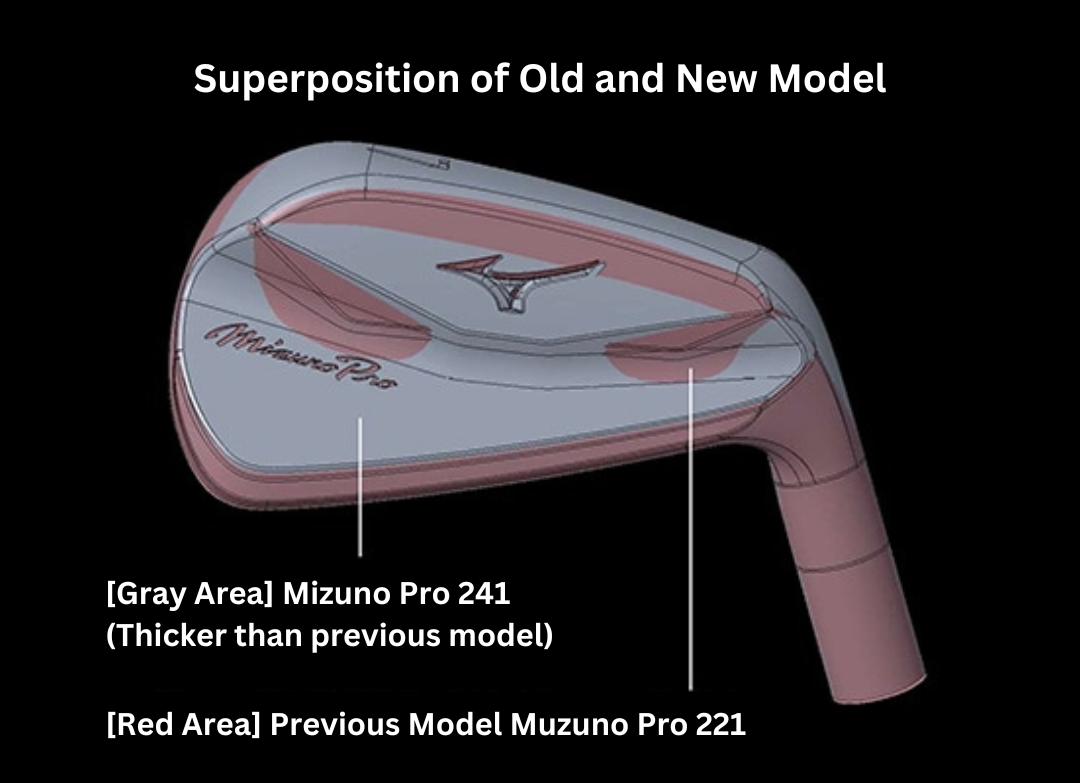

Pursuing The Ultimate Feel, The Muscle Back

Pursuing an even more solid feel by thickening the back of the ball hitting area

Pursuing an even more solid feel by thickening the back of the ball hitting area

The Mizuno Pro 241 is a pure shot-makers muscle-back with mass accumulated centrally behind impact. A result of the pursuit of fine design details made possible through the long-term relationship between Mizuno's R&D team and its exclusive Grain Flow Forging plant in Hiroshima, Japan.

Compact Size

Based on the classic muscle back iron, we pursue a shape that is easy to operate, and the entire head is designed to be compact. We have further improved the operability of short irons.

Fusion of Technology & Craftsmanship

A fusion of Mizuno's unique technology and the techniques honed by craftsmen. We pursued Mizuno's unique beautiful shape.

The Feel of Forging, The Flight of Chromoly

The flight of chromoly and the feel of soft iron coexist in one set

The flight of chromoly and the feel of soft iron coexist in one set

The Mizuno Pro 243 is a manufacturing masterpiece – more compact and precise than its predecessor, yet faster from the face and more satisfying at impact. Improvements in performance only made possible through the long-term relationship between Mizuno's R&D team and its exclusive Grain Flow Forging plant in Hiroshima, Japan.

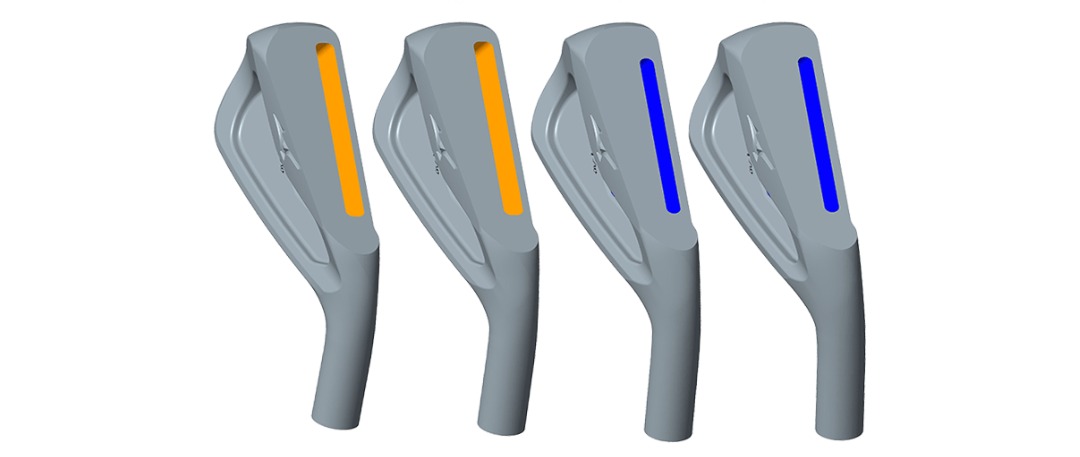

New Flow Micro Slot Structure

A player's cavity iron that pursues distance performance, forgiveness, and distance pitch in a compact shallow cavity iron while maintaining the operability and feel that elite players desire.

New Flow Micro Slot Structure: Slot Design by Count

・#4 / #5 Widest overall slot ⇒ Deeper center of gravity, easier to hit high trajectory

・Narrow slot width across #6/#7 ⇒ Smooth connection to #8 with no slot

・#8~Pw/Gw No slot to pursue the good feel of forged soft iron

Appearance Like a Muscle Back, Gentleness & Flight

Hot Metal Blade The flight of chromoly and the good feel of soft iron coexist in one set

Hot Metal Blade The flight of chromoly and the good feel of soft iron coexist in one set

The Mizuno Pro 245 is measurably quicker again from the face than the Mizuno Pro 243 but also easier to launch – due to a complex hollow body construction and internally suspended Tungsten weight. Packed into a staggeringly sleek chassis, the Mizuno Pro 245 showcases more than any model how rapidly Mizuno’s Grain Flow Forged process has evolved.

“There’s so much to the Mizuno Pro 245 for an iron of its size and shape. A multi-piece Grain Flow Forged Chromoly construction, suspended Tungsten weight and multi-thickness face. Impossible without Mizuno evolving its Grain Flow Forging process in Hiroshima. It takes a depth of manufacturing experience to push the envelope this far.”

“There’s so much to the Mizuno Pro 245 for an iron of its size and shape. A multi-piece Grain Flow Forged Chromoly construction, suspended Tungsten weight and multi-thickness face. Impossible without Mizuno evolving its Grain Flow Forging process in Hiroshima. It takes a depth of manufacturing experience to push the envelope this far.”

DAVID LLEWELLYN – Director of R&D

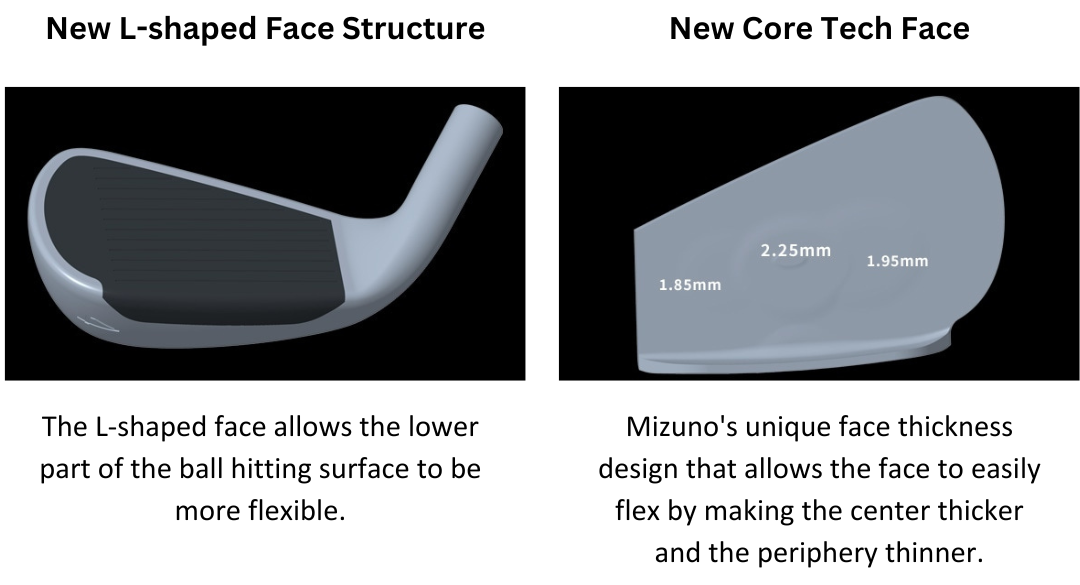

Achieved the Highest Rebound In the History of Mizuno Forged Irons

The new Coretech face has improved repulsion by making the lower center part (near the ball hitting area) even thinner than the previous Mizuno Pro 225.

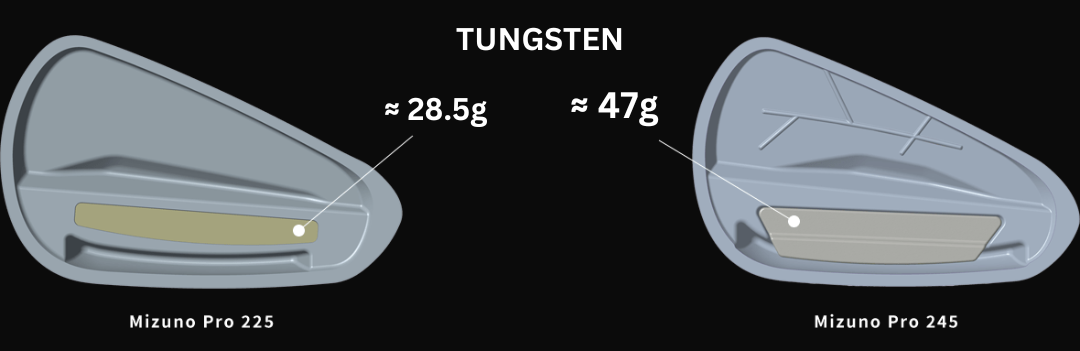

Tungsten Structure for Gentleness & Flight

Approximately 1.6 times more tungsten than the previous Mizuno Pro 225 is placed at the lowest possible position (#4-7)

・Designed with a low center of gravity and a deep center of gravity

・Expanded the sole meat part and increased the high initial velocity area*

*Comparison with our conventional product

*Comparison with our conventional product

A Driving Iron with Great Distance that Meets The Needs of Elite Golfers

Flying material Nickel chromoly hot metal blade iron

Flying material Nickel chromoly hot metal blade iron

The Mizuno Pro Fli-Hi has become a fixture with the majority of Mizuno’s tour players. An easy launching, powerful long iron replacement that flows seamlessly into either the Mizuno Pro 241, 243 or 245 full iron set. With a chassis now fully upgraded to 4335 Nickel Chromoly for elevated ball speeds.

New L-shaped Face Structure/ New Core Tech Face Improves Repulsion / Expands High Initial Velocity Area

Blackout Cosmetic & Black Top Edge

Blackout Cosmetic & Black Top Edge

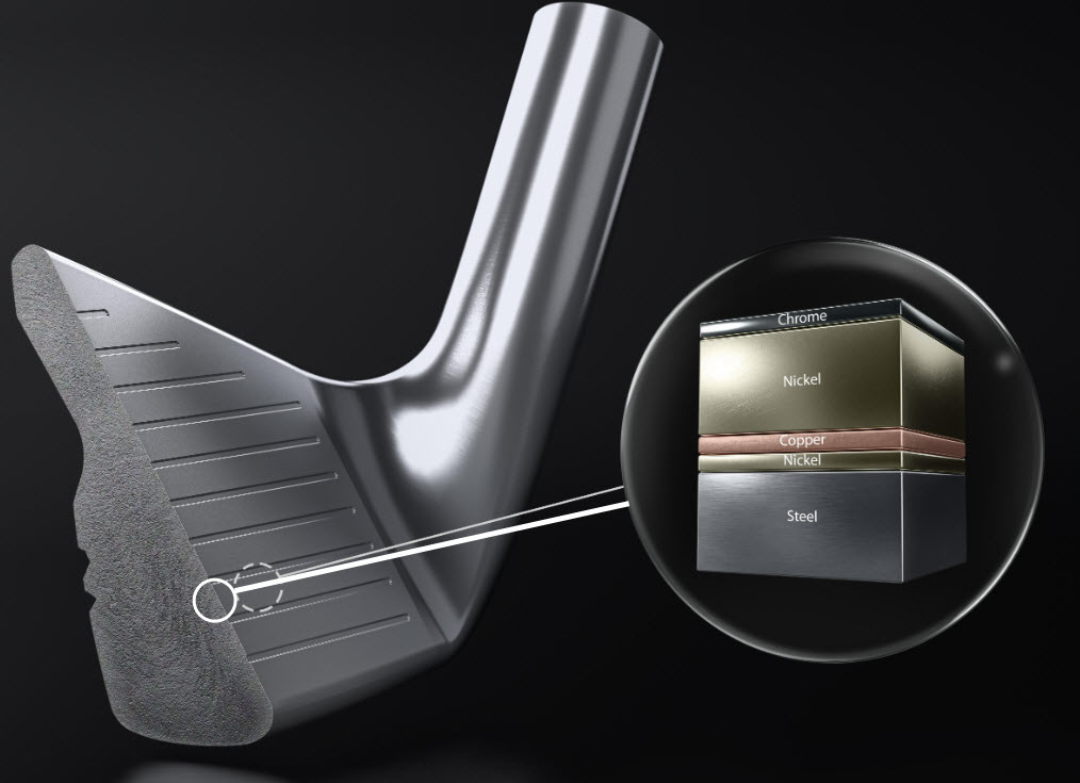

Pursuit of Feel

Copper Under Plating

Adopted in Mizuno Pro 241/243/245

Adopts copper under plating. Although the difference is slight, the feel at impact is softer, and the contact time of the ball on the face seems longer than usual.

Harmonic Impact Technology

Adopted in Mizuno Pro 241/243/245/FLI-HI

Mizuno's particular hitting feel is designed using the latest technology. The pitch, volume, and tone of the sound, which affect the feel of the ball, are tuned in units of tens of hertz. This unique Mizuno design method creates a comfortable hitting feel that is unique to Mizuno.